In the 1970s, Toyota fully implemented its Just-In-Time (JIT) manufacturing system, tailored to eliminate waste by producing only what is needed, when it is needed, and in the exact amounts required.

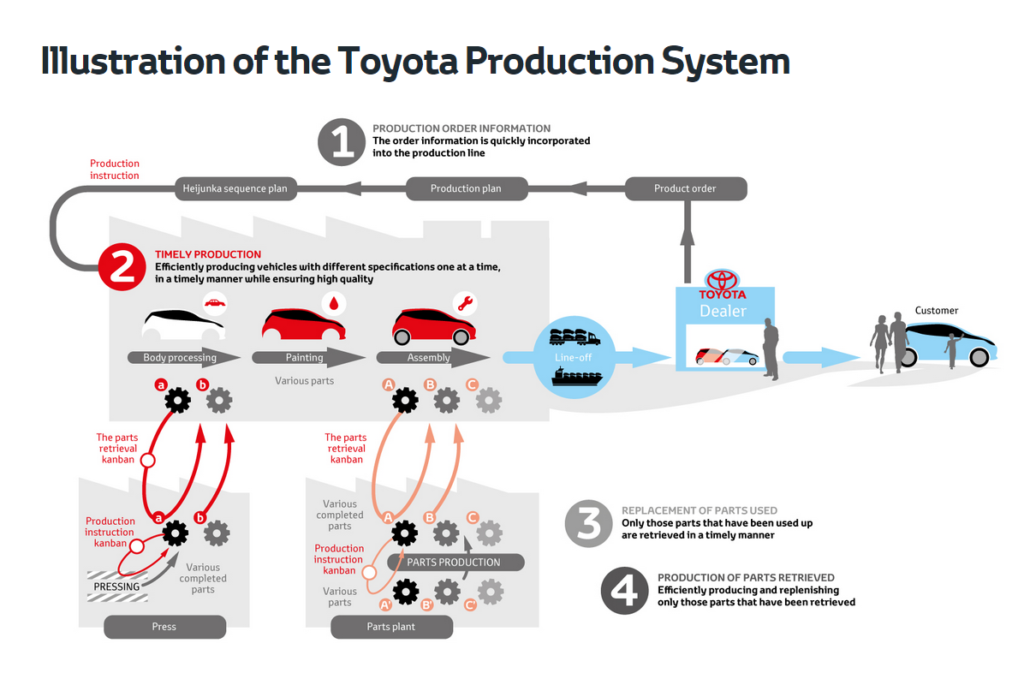

JIT is a ‘pull’ system that delivers components to assembly lines only when needed and in the exact quantities required.

This approach simultaneously orchestrates production and transport throughout the entire assembly sequence, both within and between processes.

The primary goals of JIT are twofold:

1. Minimize warehouse space and inventory carrying costs

2. Maximize operational efficiency

To achieve this, Toyota relied on Kanban boards for ordering signals, ensuring precise component delivery to workstations just before they were needed.

Inside-out, the JIT system fundamentally transformed Toyota’s production, supply chain management, and corporate culture.

It led to reduced costs, increased efficiency, and improved quality by minimizing inventory and optimizing processes.

This internal shift has reinforced Toyota’s values of efficiency and quality and promoted a culture of continuous improvement and employee empowerment.

Outside-in, JIT positions Toyota as a leader in manufacturing innovation and efficiency.

It strengthens the brand by demonstrating a commitment to quality and continuous improvement, appealing to consumers who prioritize reliability and cost-effectiveness.

This operational philosophy showcases how deeply integrated business practices can enhance brand perception and set industry standards.

The measurable impact of JIT on Toyota’s brand:

- Quality Rankings: In the 1980s and 1990s, Toyota consistently ranked among the top 3 automakers in J.D. Power Initial Quality Studies, often holding the top spot and outperforming luxury brands.

- Reliability Ratings: Throughout the 1990s and 2000s, Toyota vehicles frequently topped Consumer Reports reliability charts. In 2002, Toyota’s Lexus brand ranked first in reliability for all 30 models it had produced over the previous decade.

- Brand Value: According to Interbrand, Toyota’s brand value grew from $21 billion in 2000 to $53 billion in 2013, regaining its position as the world’s most valuable automotive brand.

- Market Share: Toyota’s U.S. market share grew from about 3% in 1970 to over 14% by 2008. Globally, Toyota became the world’s largest automaker by sales in 2008.

- Price Premium: Studies in the 2000s showed that Toyota could command a price premium of 5-7% over comparable models from American manufacturers.

By adopting JIT, Toyota didn’t just change its operational tactics—it redefined industry approaches to manufacturing and inventory management, proving that an authentic brand emerges from aligning core business practices with strategic brand development.

Leave a Reply

You must be logged in to post a comment.